(19) 1- inch deep form tapped holes from both sides of a large aluminum die casting in under 14 seconds part to part. With broken tool detection, hydraulic clamping and light curtain/auto door this machine type is ready for robotic integration for full unattended operation.

- Shuttle type machine performs (2) face mill and (28) drill operations

- On 40” aluminum automotive cross member in 78 seconds complete

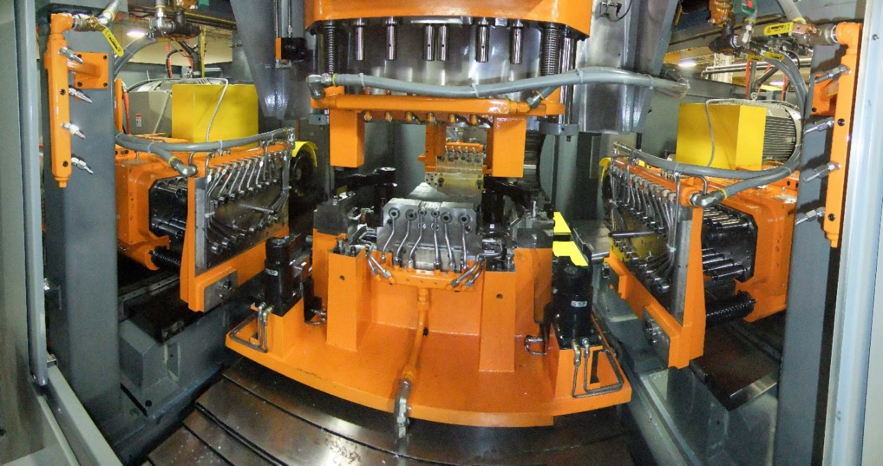

Vertical multiple spindle drilling, tapping or spot facing machine maximizes operator efficiency with hydraulic part clamping and servo controlled feed rates.