Rotary dial machines by Key Products are engineered to execute nearly every type of machining operation – on all sides of a part. This may include CNC contouring, as well as many other customer-specific application requirements.

Capable of very short cycle times (often as low as 12 to 14 seconds), you can rely on Key Products’ rotary dial machines to enhance your assembly efficiency and output.

Rotary Dial Machine Examples

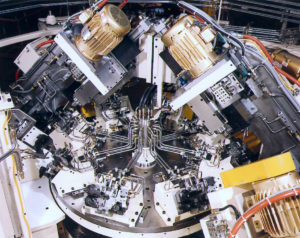

Six (6) Station Rotary Transfer – Drill, Ream & Contour Mill Aluminum Casting

- Six (6) Hydraulic Clamp Fixtures

- Auto Unload

Turnkey pricing for above machine results in piece part price under 10 cents each.

Part: Die casting.

Machining operations:

- Vertical:

- Drill and chamfer two holes

- Drill two holes

- Ream two holes

- Horizontal:

- Drill 14 holes

- CNC contour mill two slots

Production: 600 parts per hour with manual load. Automatic load available.

Eight (8) Station Rotary Transfer – Drill, Ream & Mill Cast Iron

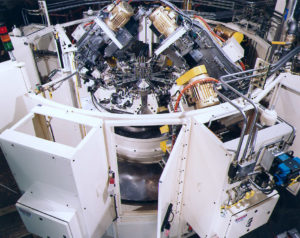

Ten Station Index on Index Machine

Machining Operations: Mill, Drill, Ream & Tap

Base Diameter. – 130″

Main Index Table – 87″

Small Tables – 18″

Machine Cycle Time: 15 Seconds – 240 Pieces Per Hour

Ten 18″ Index Fixtures

Servo Drive Tables With Face Gears For Indexing Accuracy

Learn More About Our Rotary Dials

Need more information on Key Products’ rotary dial machines? Contact us today.