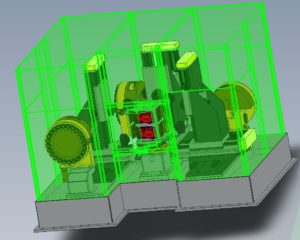

Are you in the market for a versatile machining solution? Key Products can design and construct Flex Centers to allow for the productivity of multiple tools in the cut simultaneously – such as a dial machine or a transfer process.

This solution is unique in that it’s highly adaptable, in regards to change over, and offers a number of advantages:

- Uses the same tombstone fixture concept as a standard horizontal machining center, so as your volumes go up, you can simply put the parts on our flexible production machine and get three (3) tools in the cut

- Each station is equipped with an automatic tool-changer for 20 tools

- Option for multi-spindle head drilling or tapping multiple holes

- For families of parts, simply call up the program and run a new design

- The machine can be built with different travels and configurations

- The show machine has 24 inches of travel, 3100 rpm at the spindle, and ISO 50 taper

- Each station can move to assist the machine on the side of the part at the adjacent station

- Handles two (2) or three (3) machining stations depending on the part requirements

Flex Center Options for Each Station:

- HSK tooling

- 1000 psi thru coolant

- Up to 42000 RPM spindle

Request More Information

Would you like to learn more on how our versatile flex centers can unlock your production potential? Contact Key Products today.